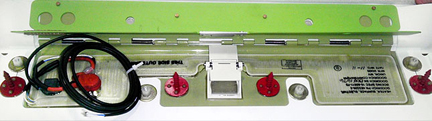

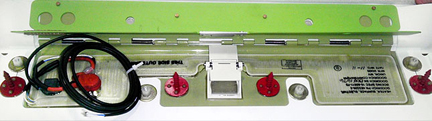

Alarin Aircraft Hinge manufactures aircraft hinges that have broad interior and exterior applications in commercial and military aircraft. These applications range from flight critical to common functionality. Within a prime manufacturer's range of commercial aircraft, for example, you may find an Alarin hinge manufactured from aluminum bronze assisting with elevator motion, a hinge manufactured from stainless steel on the air exhaust system or cargo door or aluminum MS hinges manufactured by Alarin with a line-grain finish complementing the design of an interior galley system. The same is true for a wide variety of military aircraft.

Alarin is a focused hinge manufacturer with decades of experience manufacturing precision, close-tolerance aircraft hinges for the world's leading aerospace customers.

Our wide range of capabilities has allowed Alarin to attract, and retain as long-term customers, the largest and most demanding aircraft manufacturers. Our in-house capabilities

cover the broad spectrum from order receipt to product delivery and support including:

| ▶ Procurement |

▶ Manufacturing |

| ▶ Programming |

▶ Inspection |

| ▶ Supply Chain Management |

▶ Contract Management |

| ▶ Tooling Design and Fabrication |

▶ Customer Support |

As a dedicated hinge manufacturer, our equipment includes unique manufacturing equipment designed and built by Alarin specifically to manufacture our precision hinges.

We are experienced in manufacturing aircraft hinges of all sizes from a variety of raw materials including:

| ▶ Extruded Aluminum |

▶ Other Aerospace Materials |

| ▶ Billet Aluminum |

|

| ▶ Stainless Steel and Other Steel Alloys |

|

The company maintains and increases its capacity as necessary to allow us to be responsive to new and existing customers. All of these capabilities, combined with the strength of our organization, systems and procedures, are designed to ensure high quality and on-time delivery.

Alarin has long-term relationships with the leading raw material suppliers and maintains stocking levels of key extrusions and other raw materials to ensure fast turn-around to meet customer requirements.

ENGINEERING

Alarin's engineering department has years of experience transforming our customers' designs into finished products. Our engineering staff is responsible for designing the manufacturing plans for each product as well as the Numerical Control programs used on our CNC production equipment. Alarin's engineering personnel have a wealth of experience in aircraft hinges and use this expertise to also design the tools and fixtures necessary to machine our products in the most efficient manner possible. Alarin has the capability to manufacture its tooling in house, allowing us to be more responsive to the aggressive schedules often required to meet our customer's needs.

Alarin's programming capabilities include the most recent revisions of the following software:

| ▶ CATIA V5 |

| ▶ Mastercam X6 |

| ▶ BobCAD-CAM |

AAH has a number of customer approvals for Digital Product Definition including Boeing D6-51991 and Triumph Aerostructures – Vought Aircraft Division SQR-004.

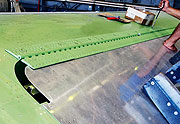

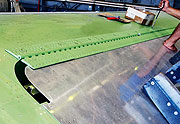

MANUFACTURING

Alarin believes in using the right equipment for the required application. This strategy allows us to maximize capacity, offer attractive lead-times, achieve quality that meets or exceeds customer requirements and deliver cost-effective products on-time. Alarin's mix of production equipment is designed specifically to manufacture aircraft hinges that conform to our mix of product capabilities. Our equipment includes:

| ▶ |

Proprietary and industry leading surface finishing equipment including machines for the application of line-grain finishes |

| ▶ |

Multi-axis 50-taper CNC machines suitable for alloy steel, and other hard metals |

| ▶ |

Multi-axis CNC machines for light alloy manufacturing |

| ▶ |

Coordinate Measuring Machine and other inspection tools |

| ▶ |

Optical comparator, grinders and other tools to maximize cutter effectiveness and drill-point geometry |

Alarin's employees undergo extensive training to ensure that they maximize their effectiveness and efficiency and manufacture precision hinges of the highest quality. Our low turn-over ensures a stable workforce with the experience and skills necessary to meet our demanding customers' requirements. A number of our manufacturing personnel have over 25 years of service to the company.

Alarin focuses extensively on lean manufacturing and the company seeks to exceed our customers' goals and expectations by promoting simplicity and organization in the work place. Embracing the 5S lean principles allows Alarin Aircraft Hinge to improve its overall product quality and promote a safe work environment. All employees within the organization implement adequate practices that focus on building quality into every aspect of the manufacturing process.

CUSTOMER SUPPORT

Alarin differentiates itself through exemplary customer service. Our size allows us to have the responsiveness required by our customers and our capabilities, expertise and experience allow us to work effectively with the largest aerospace customers in the world. The success of Alarin's focus on customer service is evidenced by the longevity of our customer relationships and our superior quality and on-time delivery ratings with our customers.

Alarin can support customer requirements of all types including single orders of all sizes for precision hinges, order fulfillment through inventory management systems such as Min/Max and statements of work under long-term contracts. Alarin has the most advanced supply chain technology platforms in place to allow us to work with our customers seemlessly:

Sales to international customers are a significant portion of Alarin's business and we are in compliance with all ITAR, DFAR and EAR requirements. In order to best serve our customers around the world, Alarin's customer service hours are 7:30 a.m. to 5:00 p.m. Pacific time, Monday through Friday.